News

Vital Controls Exactly Where They are Needed – With a Purpose-Built Control and Indicating Board

Tweet

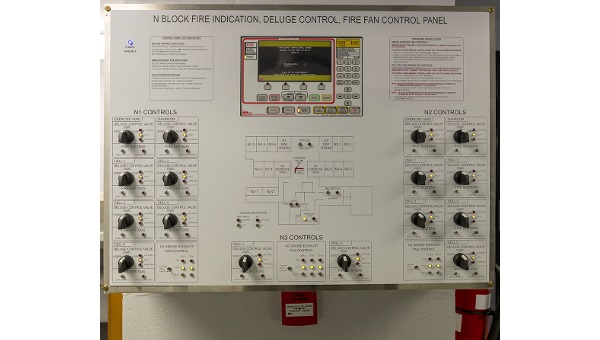

A purpose-built control and indicating board simplifies the control and monitoring of automatically-controlled equipment such as ventilation fans, dampers, and water deluge systems. A well-designed board allows facility staff and fire-fighters to quickly assess the system’s status. And if manual intervention is required, a purpose-built board helps incident managers make the right decision at the right time.

A typical purpose-built control and indicating board (CIB) has clearly-labelled switches, push-buttons, and indicators, together with concise instructions for system users. Initial concept drawings are usually developed by the installation contractor or consulting engineer, in close consultation with the local Pertronic office. Staff at the Pertronic office consult the Pertronic factory at appropriate stages of the design process, to ensure that the proposed design is consistent with Pertronic production and quality requirements.

The board’s layout and content needs to be designed around the specific characteristics of each individual project. The location may be critical. For example, it’s easier to decide whether to manually over-ride the automatic process if the control board allows you to see what is happening.

Mat Farmer, Project Manager at Endfire Engineering in Darwin, regularly uses Pertronic purpose-built CIBs on fire system projects. Mat recommends checking a full-size mock-up on-site before committing to the design. “It gives you a chance to have a final look at it,” he said. “That’s pretty important.” Purpose-built CIBs are often laid out as “mimics”, with the switches, press-buttons, and indicator LEDs positioned on a floor-plan or map of the facility. An on-site mock-up makes it easy to spot design problems, such as a mis-oriented floor plan.

Forward Planning is Crucial for Success

Purpose-built control and indicating boards are built and tested by the panel assembly group at our Wingate factory. Often the CIP is built some weeks after the fire indicator panel has left the factory. This means the installation team has been installing the fire indicator panel and connecting the system cabling, while the factory is building the CIB. In these situations the CIB must be fitted onto the fire indicator panel on site. A detailed planning process is crucial to ensuring that the CIB mates seamlessly with the FIP.

To succeed, everyone must work to the same plan, a process which can take weeks. To create this plan, Pertronic branch office staff work with the contractor and consulting engineer to finalise not only the graphics, layout and text, but also to schedule in advance the connection and labelling of every item on the CIB. The factory builds to this schedule. The fire indicator panel is configured according to this schedule. Having built hundreds of CIB, the planning process has been tuned to a fine art.

The CIB design must be reviewed and approved by many different people, as building will not begin until the complete design is approved. Project managers need to allow enough time for design development, to ensure that all necessary consultation and approval processes can be completed. Every design iteration effects the entire plan.

Our purpose-built CIBs have been used on many projects throughout Australia. Clear communication and well-proven planning processes ensure their success. “Usually,” said Mat Farmer, “we just plug in the cables in the right order, and it goes.”

Pertronic purpose-built control and indicating boards are manufactured to the same exacting standards as all Pertronic products. We are very pleased that our purpose-built boards have been used in so many projects throughout Australia. We are always happy to discuss project requirements with our customers.

Contact us for more information about Pertronic Purpose-Built Control and Indicating Boards

(Revised 17 Sep 2020. CIBs were previously called control and indicating panels.)

CLICK to CALL US NOW

CLICK to CALL US NOW